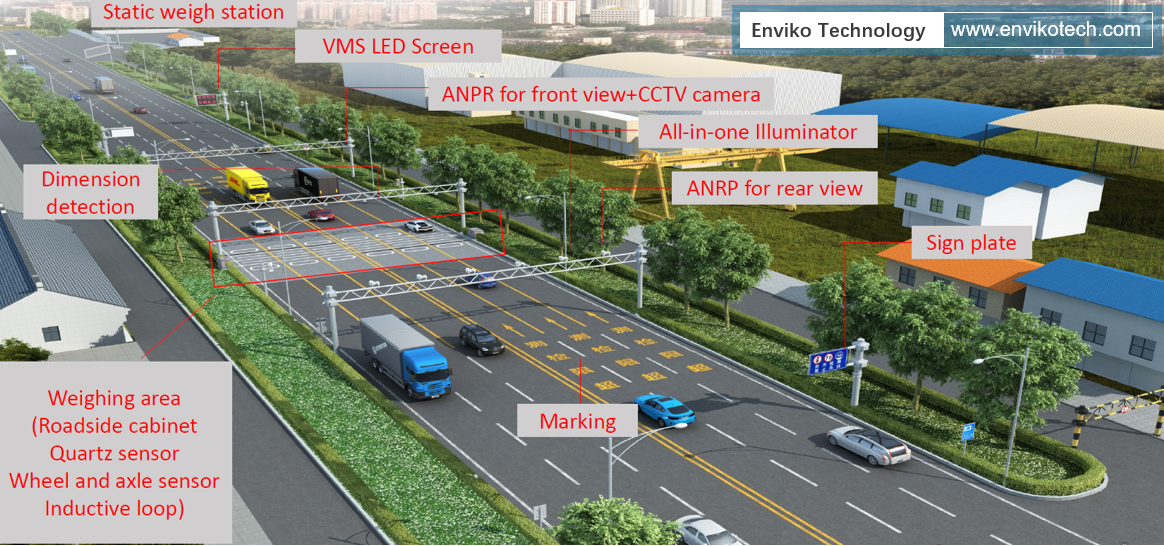

Weigh-In-Motion (WIM) is a technology that measures the weight of vehicles while they are in motion, eliminating the need for vehicles to stop. It uses sensors installed beneath the road surface to detect pressure changes as vehicles pass over them, providing real-time data on weight, axle load, and speed. WIM systems are widely used in traffic management, overload enforcement, and logistics to improve efficiency and safety.

WIM offers significant benefits, including reduced traffic disruption, real-time monitoring, and improved road safety by detecting overloaded vehicles. Among the various sensor types, quartz sensors are particularly suitable for High-Speed Weigh-In-Motion (HSWIM) due to their high accuracy, durability, and ability to withstand harsh environmental conditions. Quartz sensors, such as the CET8312-A, provide consistent performance even at high speeds, making them ideal for applications requiring precise and reliable weight measurements in fast-moving traffic scenarios.

The following introduces two important testing methods to be conducted before installing the Quartz Sensor: Insulation Test and Waveform Test.

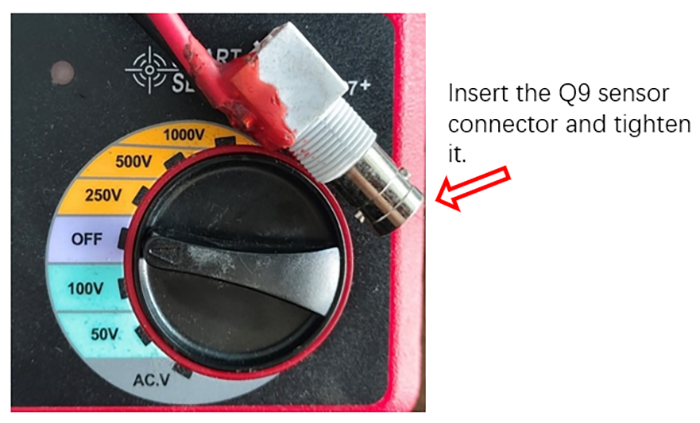

- Insulation Test Method

1) Insert sensor Q9 head into megohmmeter socket

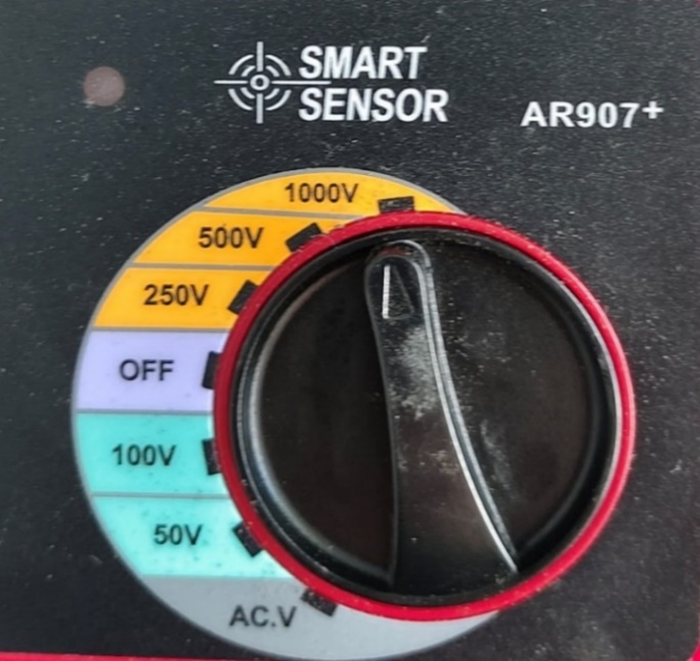

2) Set megohmmeter to 1000V position (prohibited to use 2500V position)

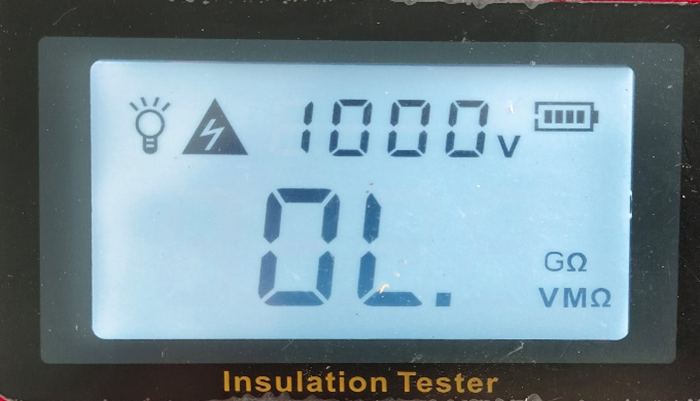

3) Turn and press test switch clockwise, hear "beep" sound, red indicator light in upper right illuminates to start test, test time should not be less than 5 seconds

1) Test results as shown:

Display result OL unit (GΩ): Optimal performance

Display result 163 unit (MΩ): Cannot be used

IMPORTANT NOTE!!! After testing sensors with megohmmeter, sensors accumulate large amounts of electrical energy. Sensors must be short-circuited to release stored energy. Connecting to data acquisition or weighing equipment without discharge after insulation testing will destroy equipment with high voltage, rendering it unusable.

1.Waveform Test Method

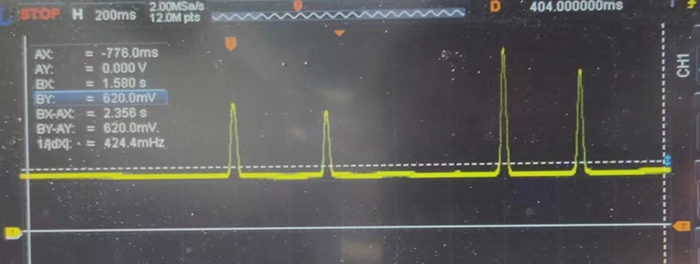

1) Insert sensor Q9 head into oscilloscope "CH1" socket, adjust time to 200ms and voltage to 500mv, or adjust according to site conditions

2) Strike sensor at any point with rubber hammer, oscilloscope should show signal waveform output

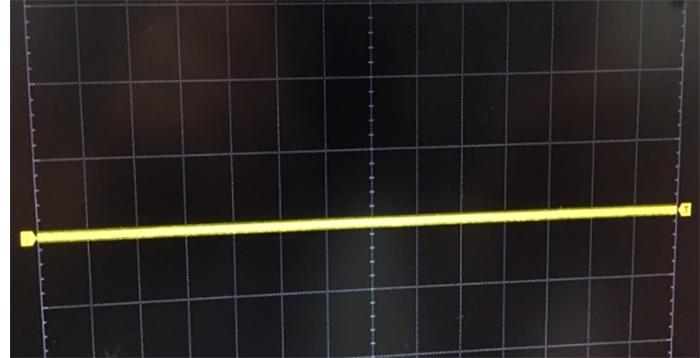

No signal output as shown above

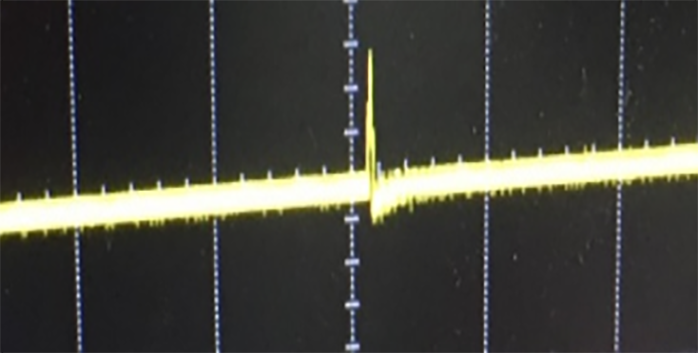

Signal output as shown above

Positive waveform

Negative waveform

1.Sensor Quality Assessment

Insulation Assessment Standards:

- OL unit GΩ: Optimal performance

- Greater than 10 GΩ: Good condition

- Less than 1 GΩ: Usable

- 300MΩ and below: Defective (Scrap)

Enviko Technology Co.,Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Chengdu Office: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Hong Kong Office: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Post time: Jan-23-2025