The Enviko 8311 Piezoelectric Traffic Sensor is a high-performance device designed for collecting traffic data. Whether installed permanently or temporarily, the Enviko 8311 can be flexibly installed on or below the road, providing accurate traffic information. Its unique structure and flat design allow it to conform to the road profile, reduce road noise, and improve the accuracy and reliability of data collection.

How piezoelectric load cells work

The Enviko 8311 sensor is divided into two types:

● Class I Sensor (Weigh In Motion, WIM): Used for dynamic weighing applications, with an output consistency of ±7%, suitable for applications requiring high-precision weight data.

● Class II Sensor (Classification): Used for vehicle counting, classification, and speed detection, with an output consistency of ±20%. It is more economical and suitable for high-traffic management applications

Application Fields

1.Road Traffic Monitoring:

o Vehicle counting and classification.

o Traffic flow monitoring, providing reliable traffic data support.

2.Highway Tolling:

o Dynamic weight-based tolling, ensuring fair and accurate toll collection.

o Vehicle classification tolling, enhancing toll collection efficiency.

3.Traffic Law Enforcement:

o Red-light violation monitoring and speed detection, helping to maintain traffic order.

4.Intelligent Transportation Systems:

o Integration with traffic management systems, promoting the development of intelligent transportation.

o Traffic data collection and analysis, providing a basis for traffic planning.

Technical parameters

| Model No. | CET8311 |

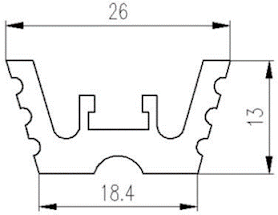

| Section size | ~3×7mm2 |

| Length | can be customized |

| Piezoelectric coefficient | ≥20pC/N Nominal value |

| Insulation resistance | >500MΩ |

| Equivalent capacitance | ~6.5nF |

| Working temperature | -25℃~60℃ |

| Interface | Q9 |

| Mounting bracket | Attach the mounting bracket with the sensor (Nylon material not recycled). 1 pcs bracket each 15 cm |

Installation Methods and Steps

1.Installation Preparation:

o Choose a suitable road section, ensuring the long-term stability of the weighing equipment and the rigidity of the road foundation.

2.Slot Cutting:

o Use a cutting machine to cut slots at designated positions, ensuring precise control of the slot dimensions.

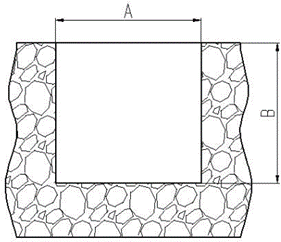

1) Cross Section dimension

A=20mm(±3mm)mm; B=30(±3mm)mm

2) Groove’s length

The length of the slot should be more than 100 to 200 mm of the total length of the sensor. Total length of sensor:

o i=L+165mm, L is for brass length (See the label).

3.Cleaning and Drying:

o Clean the installation slot with a high-pressure cleaner, ensuring the slot is free of debris.

4.Pre-installation Testing:

o Test the capacitance and resistance of the sensor, ensuring they are within specification.

5.Fixing Installation Brackets:

o Place the sensor and installation brackets into the slot, installing a bracket every 15 cm.

6.Grouting:

o Mix the grouting material according to the specified ratio and fill the slot evenly, ensuring the grouting surface is slightly higher than the road surface.

7.Surface Grinding:

o After the grouting has cured, grind the surface with an angle grinder to make it smooth.

8.Site Cleaning and Post-installation Testing:

o Clean the site, test the capacitance and resistance of the sensor again, and perform pre-load testing to ensure the sensor is working properly.

The Enviko 8311 sensor, with its outstanding performance, reliable accuracy, simple installation, and versatile applications, is an ideal choice for traffic monitoring and management systems. Its unique design and high-quality materials ensure long-term stable performance. Whether for dynamic weighing, vehicle classification, or speed detection, the Enviko 8311 sensor provides precise data, supporting the development of intelligent transportation systems. If you are looking for an efficient, reliable, and economical traffic sensor, the Enviko 8311 sensor is undoubtedly your best choice.

Enviko Technology Co.,Ltd

E-mail: info@enviko-tech.com

https://www.envikotech.com

Chengdu Office: No. 2004, Unit 1, Building 2, No. 158, Tianfu 4th Street, Hi-tech Zone, Chengdu

Hong Kong Office: 8F, Cheung Wang Building, 251 San Wui Street, Hong Kong

Post time: Jul-30-2024